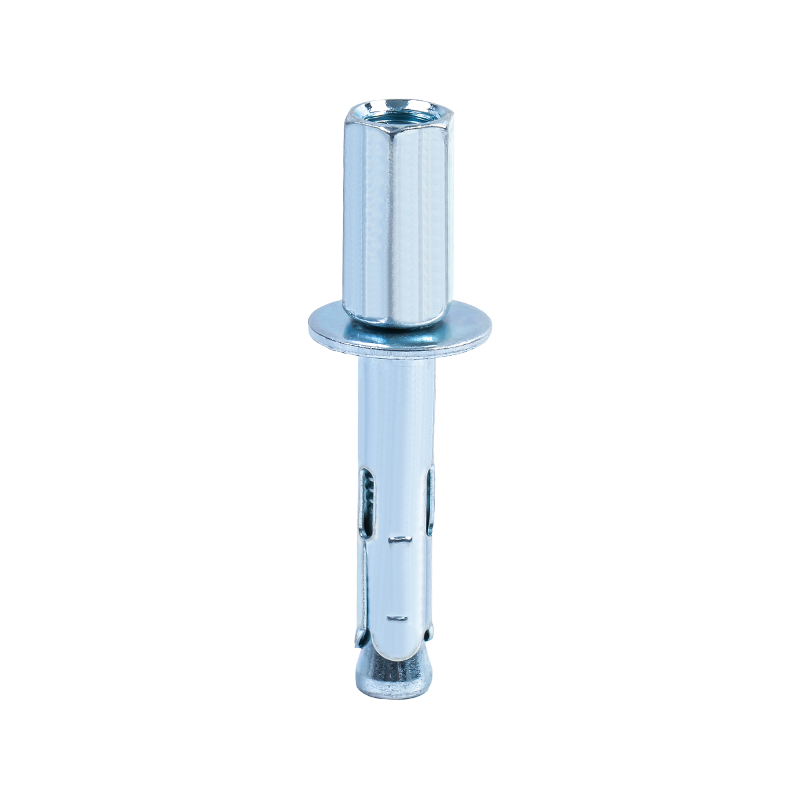

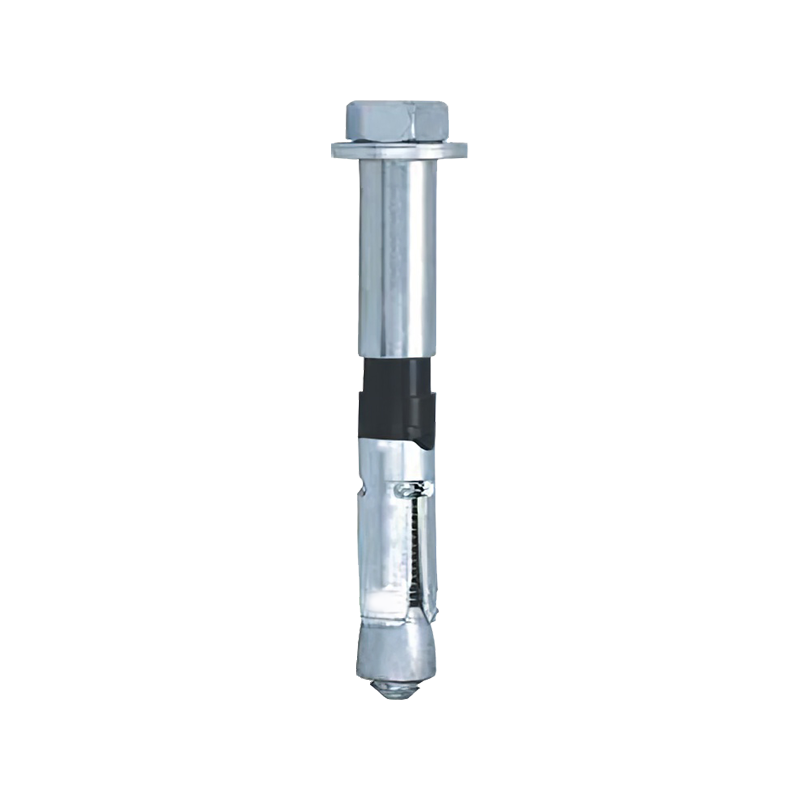

Strength and toughness of galvanized steel bolts heavy shield anchors

2024-10-23The strength and toughness of galvanized steel bolts heavy shield anchors are crucial performance indicators in various engineering applications. For galvanized steel bolts, their strength is mainly determined by the type of substrate and its treatment process. Galvanized steel usually uses high-strength carbon steel as the substrate, and the yield strength and tensile strength of these materials can be improved by appropriate alloying elements.

Yield strength: This is the critical point at which the material begins to deform plastically after being subjected to force. For galvanized steel bolts, the yield strength is usually between 400-800 MPa, depending on the grade and manufacturing process of the material.

Tensile strength: Tensile strength is the maximum stress that a material can withstand when stretched. The tensile strength of galvanized steel bolts is usually higher than the yield strength, which means that they are not prone to breakage under normal working conditions.

For galvanized steel bolts, toughness is an important indicator to ensure the safety of the structure, especially under dynamic loads or impact loads.

Impact toughness: Galvanized steel bolts can still maintain good toughness under low temperatures or impact conditions, which is an important requirement for their design. By controlling the alloy composition and heat treatment process, the impact toughness of the material can be significantly improved to adapt it to the changing working environment.

Fatigue strength: The fatigue strength of the material is critical under long-term cyclic loads. The fatigue limit of galvanized steel bolts is generally higher, which means that they are less prone to fatigue failure under repeated loading conditions. This is especially important for long-term load-bearing structures.

Contact Us