How the Bolt Heavy Duty Shield Anchor's design improves its load-bearing capacity

In modern construction projects, the design and performance of the anchoring system is one of the key elements to ensure the safety and stability of the structure. Since its establishment in 1999, Yuyao Nanshan Development Co., Ltd. has focused on the research and development and production of high-performance anchoring products.

Selection of high-strength materials

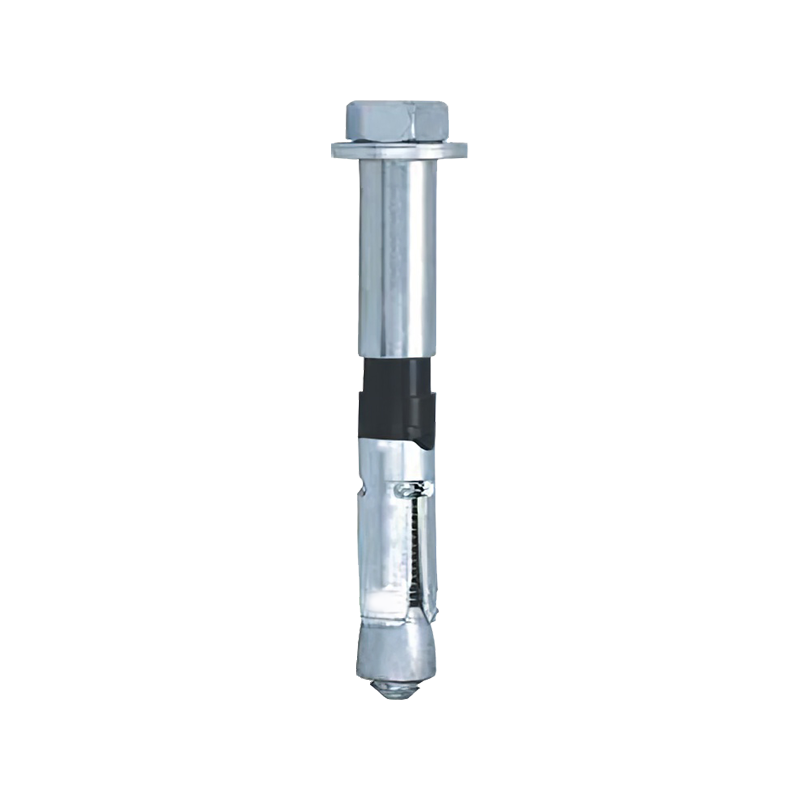

The Bolt Heavy Duty Shield Anchor's load-bearing capacity comes from its selection of high-quality materials. The anchor is made of high-strength alloy steel with extremely high tensile strength and shear resistance. Through a rigorous heat treatment process, the toughness and durability of the material are enhanced, making it less prone to plastic deformation or fracture when subjected to heavy loads. In addition, Nanshan strictly controls the quality of material procurement to ensure that each batch of materials meets international standards, thereby improving the overall reliability of the product.

Optimized design structure

The design structure of the Bolt Heavy Duty Shield Anchor has been carefully optimized to maximize its load-bearing capacity. The shape and size of the anchor have been computer simulated and tested in practice to ensure optimal performance under a variety of load conditions. Specifically, the anchor head part of the anchor adopts a conical structure design, which can effectively disperse the pressure applied to the anchor point and reduce concentrated stress, thereby significantly improving the overall load-bearing capacity.

Advanced production technology

Yuyao Nanshan Development Co., Ltd. introduces advanced production equipment and processes to ensure that each Bolt Heavy Duty Shield Anchor can meet strict quality standards. The company uses automated production lines and high-precision testing equipment to ensure that every link in the production process is strictly controlled. By implementing the ERP system, Nanshan can monitor the production process in real time and promptly discover and solve problems that may affect product quality. This refined production management not only improves product consistency, but also provides higher reliability for anchors.

Load testing and verification

In order to ensure the load-bearing capacity of the Bolt Heavy Duty Shield Anchor, Yuyao Nanshan Development Co., Ltd. implemented a series of rigorous load tests after the product design was completed. These tests include static load tests and dynamic load tests, which are designed to simulate various conditions in actual use. These test results provide important data support for product design and improvement, ensuring that each factory-produced anchor can perform well in actual applications.

Anchoring Depth and Installation Method

The design of Bolt Heavy Duty Shield Anchor fully considers the impact of anchoring depth and installation method on bearing capacity. The installation depth of the anchor is carefully designed to ensure that it can be effectively embedded in the base material to form a stable anchoring effect. Through a reasonable installation method, the anchor can maximize its bearing capacity when subjected to tension and shear. In addition, Nanshan Company also provides detailed installation guidance to ensure that users can correctly install and use Bolt Heavy Duty Shield Anchor in actual applications, thereby ensuring its optimal performance.

What are the precautions for the installation process of Bolt Heavy Duty Shield Anchor

In modern construction and infrastructure projects, heavy-duty bolt anchors (Bolt Heavy Duty Shield Anchor) as a key anchoring solution are widely used in many fields such as steel structure high-rise buildings, bridges and tunnels. In order to ensure its superior bearing capacity and safety, a reasonable installation process is particularly important.

Preparation before installation

Before installing the heavy-duty bolt anchor, sufficient preparation is indispensable. This phase includes the following aspects:

Material inspection: Ensure that the anchors and accessories used meet the design specifications and are free of visual and functional damage or defects.

Tool preparation: Prepare appropriate installation tools, such as electric drills, wrenches and hammers, and ensure that these tools are in good working condition.

Construction environment assessment: Evaluate the environmental conditions of the construction site, including temperature, humidity and wind speed, to ensure that the installation is carried out in a suitable environment.

Determine the installation location

Before installing the heavy bolt anchor, the location of the anchor point must be determined. The installation location should be accurately marked using a level and measuring tools based on the design drawings and engineering requirements. The depth and spacing of the anchor points must meet the design specifications to ensure the best anchoring effect.

Drilling operation

The installation of heavy bolt anchors requires drilling at the specified location, and the depth and diameter of the drilled holes must meet the technical specifications and design requirements of the product. The following are key considerations in the drilling operation:

Drilling depth: Ensure that the drilling depth meets the requirements of the anchor, which should usually be slightly deeper than the length of the anchor to ensure that the anchor can be fully embedded in the base material.

Drilling Angle: Drilling should be kept perpendicular to the base material and avoid tilting to ensure accurate installation of the anchor.

Hole Cleaning: After drilling, the dust and debris in the hole must be thoroughly cleaned to ensure good contact between the anchor and the base material.

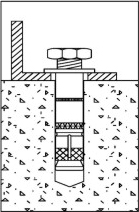

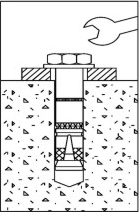

Installing the anchor

After the hole is cleaned, the heavy bolt anchor can be installed. The following points should be noted during installation:

Correct placement of the anchor: Place the anchor vertically into the hole and ensure that its bottom fits tightly with the bottom of the hole.

Use appropriate tools: Use a wrench or other tools to tighten the anchor according to the manufacturer's requirements to ensure that it is firmly fixed.

Avoid overtightening: During the tightening process, the force must be carefully controlled to avoid damage to the anchor or the base material due to overtightening.

Inspection and testing

After installation, the heavy bolt anchor must be fully inspected and tested to ensure that the installation quality meets the standards. The main inspection and testing steps include:

Visual inspection: Visually inspect the installation position, depth and tightening of the anchor to ensure that it meets the design requirements.

Load testing: In some critical applications, load testing is performed to verify the load-bearing capacity and stability of the anchors. The testing should follow relevant standards and specifications.

By strictly following the above steps, the installation quality of heavy bolt anchors can be ensured, thereby ensuring the safety and stability of buildings and infrastructure.