What are the precautions for installing Ultra Wedge Anchor?

In the construction and engineering industry, as the core component of structural connection, the professionalism and accuracy of the installation process of wedge anchors (Ultra Wedge Anchor) are crucial. Since its establishment in 1999, Yuyao Nanshan Development Co., Ltd. has been committed to the research and development and production of high-quality Ultra Wedge Anchors. With rich industry experience and technical accumulation, it has become an important player in this field.

Preparation before installation

Before installing the Ultra Wedge Anchor, it is necessary to ensure that all relevant tools and materials are fully prepared. This includes suitable drill bits, hammer tools, wrenches, dowel pins, and necessary measuring instruments. The evaluation of the installation environment cannot be ignored. It is necessary to ensure that the strength, humidity, and temperature of the concrete substrate meet the installation specifications of the Ultra Wedge Anchor. In addition, according to the specific application requirements, choosing the appropriate anchor specifications and models is a key step to ensure installation accuracy and reliability.

Drilling and cleaning

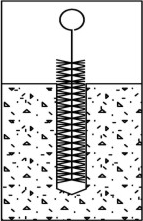

Drilling is an important part of the installation process of Ultra Wedge Anchor. First, the installation position of the anchor needs to be accurately measured and marked to ensure the accuracy and consistency of the drilling depth. During the drilling process, a drill bit that matches the diameter of the anchor should be used, and the manufacturer's recommended drilling depth and diameter should be strictly followed. After drilling, the hole must be thoroughly cleaned to remove dust and debris to ensure that the anchor can be inserted smoothly and form good friction, which is essential for subsequent load-bearing capacity.

Installation and Adjustment

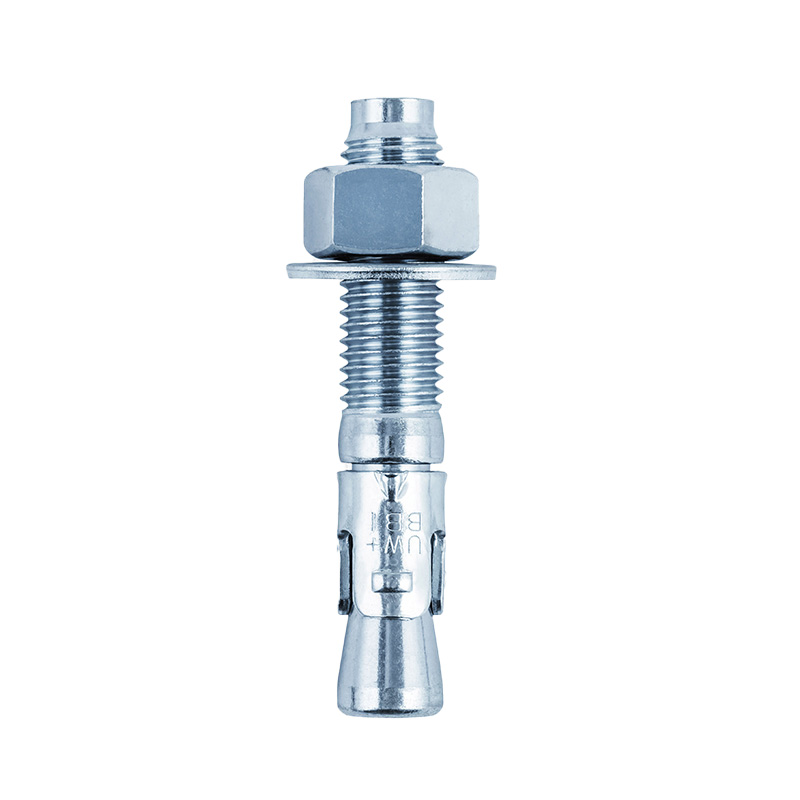

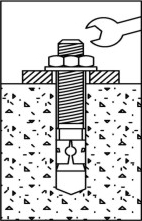

When installing the Ultra Wedge Anchor, first insert the anchor into the pre-drilled hole and tap it gently with a hammer tool until the required depth is reached. During this process, it is necessary to ensure that the anchor remains vertical to avoid deflection or damage that affects the installation quality. To prevent the anchor from moving or rotating during installation, it is necessary to use a dowel pin to fix its position. After installation, tighten the anchor with an installation wrench to ensure that it reaches the designed load-bearing capacity and ensure the safety and stability of the structure.

Inspection and Testing

After installation, the Ultra Wedge Anchor must be fully inspected and tested. This includes confirming that the anchor is installed correctly and securely, and checking for any damage or defects. At the same time, a tensile test is performed to verify the performance of the anchor under the expected load. During the test, professional testing equipment is applied, and the standards and methods provided by the manufacturer are followed to ensure the accuracy and reliability of the test results.

Yuyao Nanshan Development Co., Ltd. has a strong technical foundation and rich industry experience in the production of Ultra Wedge Anchor. The company is equipped with advanced production equipment, including imported automated production lines and precision testing equipment to ensure that each product meets international standards. By implementing an advanced ERP system, the company has achieved comprehensive monitoring and management of the production process, significantly improving production efficiency and product quality.

Application Fields of Ultra Wedge Anchor

In the field of engineering technology, anchors are key components for connecting and fixing structures, and their performance and quality directly affect the safety and stability of the entire system. Ultra Wedge Anchor has become an important choice in this field with its advanced design concept and excellent performance.

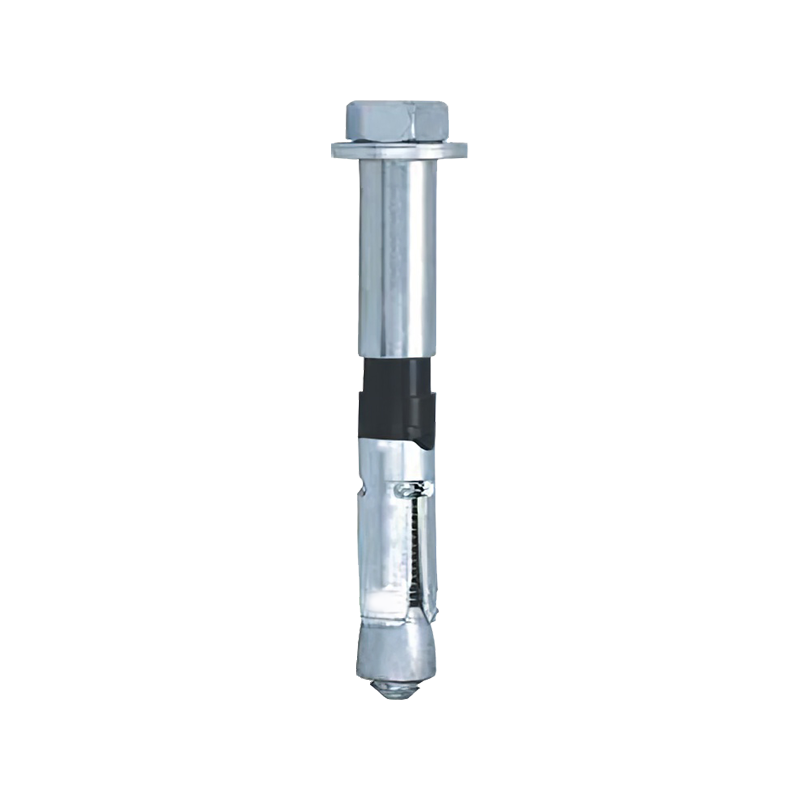

Ultra Wedge Anchor adopts a unique wedge design, which not only significantly improves the pull-out and shear resistance of the anchor, but also greatly enhances its adaptability and durability in complex environments. Its unique structural characteristics enable Ultra Wedge Anchor to provide excellent anchoring effects in a variety of substrates, such as concrete, rock and brick walls, and is widely used in many fields such as construction, bridges, tunnels, subways, water conservancy and wind power.

In the construction industry, Ultra Wedge Anchor is widely used in the reinforcement and connection of structures such as high-rise buildings, large commercial complexes and bridges. With the acceleration of urbanization, high-rise buildings and large commercial complexes have sprung up like mushrooms after rain, and these buildings have put forward extremely high requirements for the safety and stability of structures. Ultra Wedge Anchor has become an indispensable and important part of these buildings with its excellent anchoring performance and durability. It is not only suitable for connecting and fixing structural materials such as steel bars and steel plates, but also can effectively reinforce key parts such as walls, beams and columns, thereby ensuring the stability and safety of the entire building structure.

In bridge engineering, Ultra Wedge Anchor also plays a vital role. As an important channel connecting the two sides, the safety and stability of the bridge are directly related to the safety of people's lives and property. Ultra Wedge Anchor can be effectively used for bridge reinforcement and maintenance, especially in key parts such as bridge supports, piers and bridge decks. It provides reliable anchoring effect to ensure the stability and safety of bridges in various harsh environments.

In underground projects such as tunnels and subways, Ultra Wedge Anchor also shows its wide application potential. These projects usually face complex geological conditions and great construction difficulties, and have extremely high performance requirements for anchors. Ultra Wedge Anchor can provide reliable anchoring effect in these projects with its excellent pull-out resistance and shear force, as well as good adaptability, to ensure construction quality and safety.