What factors affect the anchoring force of metric wedge anchor

2025-01-21In the fields of construction and engineering, the anchoring force of the Metric Wedge Anchor is key to ensuring the safety and stability of the structure. The effectiveness of its anchoring force is affected by many factors, mainly including the nature and condition of the substrate, the material and size of the anchor bolt, the installation process and construction environment, as well as environmental factors such as temperature and humidity.

Nature and condition of the substrate

The physical properties of the substrate are the basis for influencing the anchoring force of the Metric Wedge Anchor. The strength, hardness, density and surface condition of the substrate are directly related to the anchoring effect. Taking concrete as an example, the higher the strength of concrete, the stronger the bond between it and the Metric Wedge Anchor, thereby improving the anchoring force. Furthermore, the surface cleanliness of the substrate is critical. Any impurities, oil stains or holes on the surface will significantly reduce the anchoring force. Therefore, before installation, the substrate must be thoroughly cleaned and properly prepared to ensure the best anchoring effect.

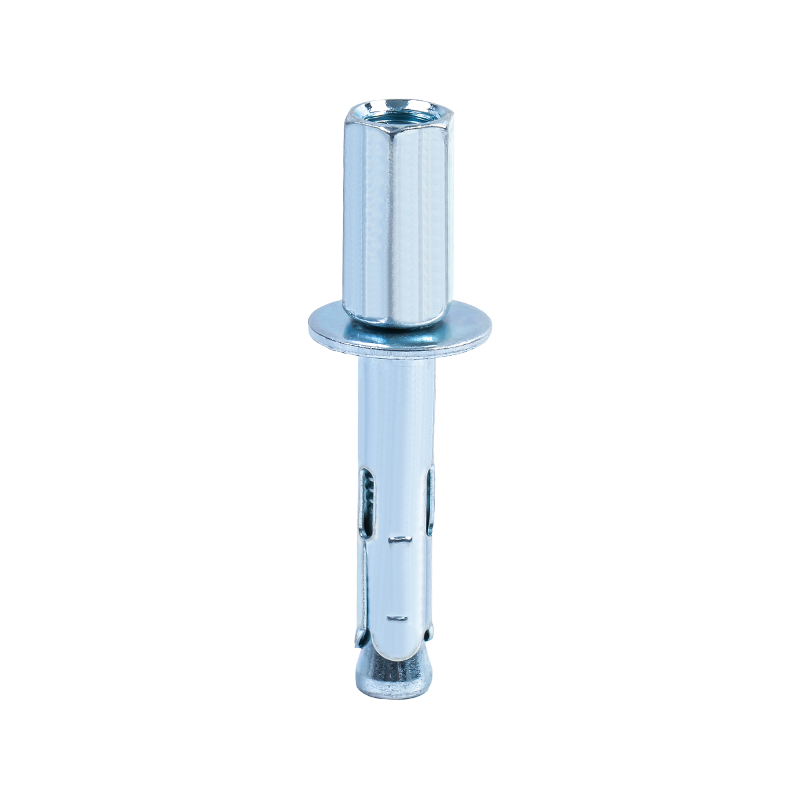

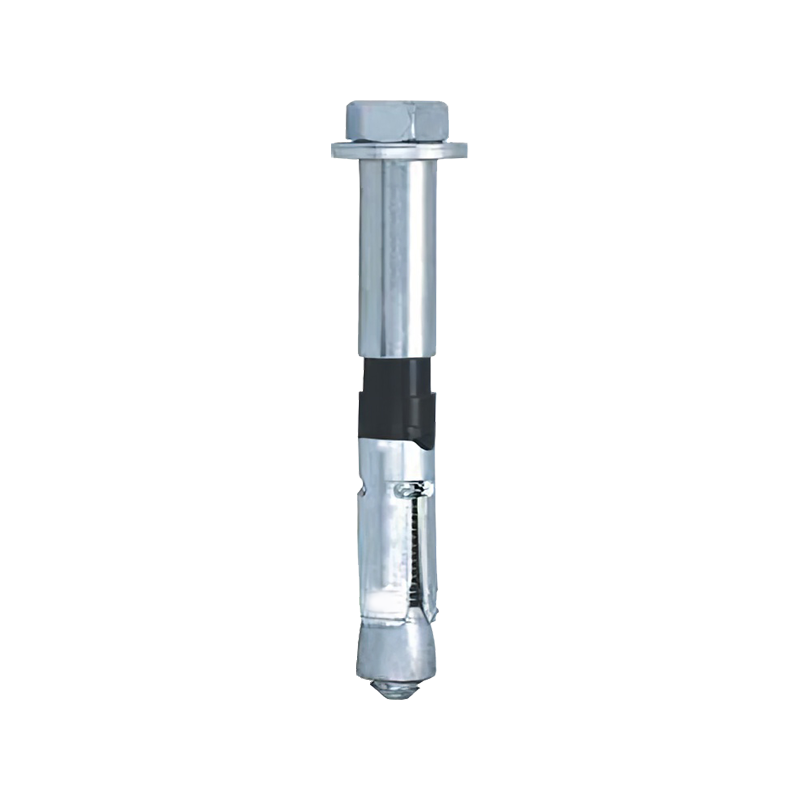

Material and size of anchor bolts

The material and size of the Metric Wedge Anchor are also important factors in determining the anchoring force. The high-quality alloy steel material not only has high strength and durability, but also can maintain stable performance under various harsh environmental conditions. The size and shape of the anchor bolt directly affect the contact area and friction between it and the substrate, which in turn affects the anchoring force. Therefore, when choosing a Metric Wedge Anchor, it is necessary to scientifically and rationally select the appropriate material and size based on the specific application scenario and engineering requirements to ensure its optimal performance during use.

Installation technology and construction environment

The standardization of the installation process and the suitability of the construction environment have a significant impact on the anchoring force of the Metric Wedge Anchor. The correct installation process can ensure that the anchor bolt is accurately inserted into the pre-drilled hole and the wedge-shaped part is fully expanded and fits tightly against the hole wall, thereby generating sufficient friction. In addition, the conditions of the construction environment cannot be ignored. In humid or harsh environments, the base material and anchor bolts are prone to rust, thereby reducing the anchoring force. Therefore, during the construction process, effective preventive measures should be taken to keep the construction environment dry and clean, and anti-corrosion coatings can be used to enhance the stability of anchoring.

Effects of temperature and humidity

Temperature and humidity are important environmental factors that affect the anchoring force of Metric Wedge Anchor. In high temperature environments, substrates such as concrete may crack and shrink, which will directly affect the bond between them and the anchor bolts. In a humid environment, rust and corrosion of the anchor bolts and substrate will also reduce the anchoring force. Therefore, the influence of temperature and humidity must be fully considered during construction, and corresponding measures must be taken to ensure the stability of the anchoring force. For example, under high temperature conditions, moisturizing measures can be taken, while in humid environments, moisture-proof measures should be implemented to ensure the durability of the anchoring effect.

Contact Us