What should I do before repairing or replacing the ultra sleeve anchor

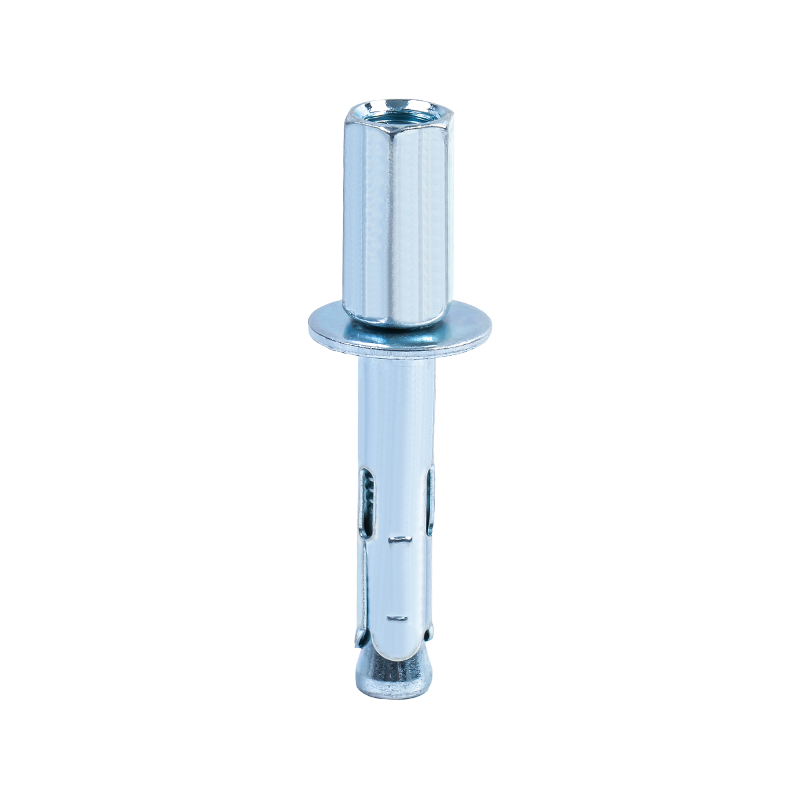

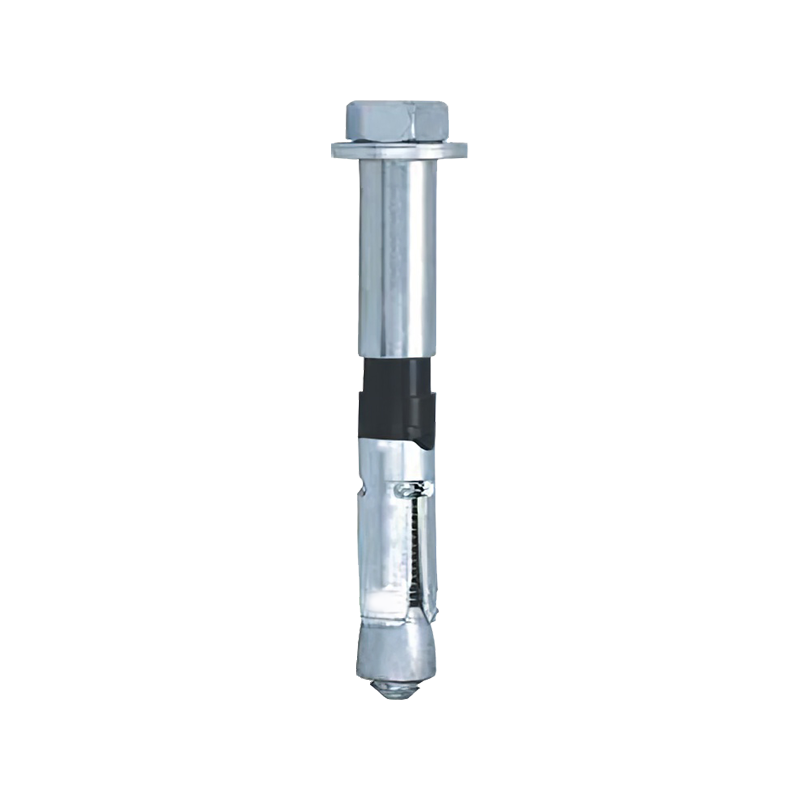

2024-11-12Ultra Sleeve Anchor is an indispensable and important anchoring component in the construction field. It is widely used in various infrastructure projects such as bridges, tunnels, and high-rise buildings. Its main function is to ensure the stability of the connection between various structural components, to withstand the design load, and to remain safe and reliable in long-term use. However, considering the diversity of the use environment, Ultra Sleeve Anchor may suffer from wear, corrosion or other forms of damage during long-term operation, so regular maintenance and replacement are particularly important. Before performing these operations, professional preparation is essential.

Before maintaining or replacing the Ultra Sleeve Anchor, you must first conduct a comprehensive assessment of its current status. This process includes a detailed inspection of the integrity, tightness, corrosion, and whether there are cracks or deformations of the anchor. If the performance of the anchor has deteriorated to the point where it cannot meet the design requirements or there is a potential safety hazard, it must be replaced. In contrast, if there is only minor damage or corrosion, repairs can be considered.

Before repairing or replacing, it is crucial to understand the type and specification of the anchor. Different types of Ultra Sleeve Anchors have significant differences in design and performance, so targeted solutions should be adopted when repairing or replacing them. At the same time, ensure that the new anchor is fully matched with the old anchor in size, material and performance to ensure the stability and reliability of the connection after replacement.

It is necessary to develop a detailed repair or replacement plan based on the evaluation results and the specific type and specifications of the anchor. This plan should cover specific operating steps, required materials and tools, safety measures, and expected completion time. In addition, the actual conditions of the work site, such as space limitations and environmental conditions, should also be considered to ensure the feasibility and safety of the plan.

When preparing materials and tools, they should be prepared accordingly according to the repair or replacement plan. This includes a new Ultra Sleeve Anchor, fasteners, cleaners, rust inhibitors, and special tools (such as wrenches, screwdrivers, hex wrenches, etc.), as well as necessary testing instruments (such as torque wrenches, thickness gauges, etc.). Ensure that all materials and tools meet relevant standards and requirements and have reliable quality assurance so that each step can be effectively performed during implementation.

In actual operation, maintenance or replacement of Ultra Sleeve Anchor should be carried out by professional technicians to ensure that all operations comply with safety regulations and industry standards. During the operation, be sure to follow relevant safety measures to ensure the safety of construction workers and the surrounding environment. Through scientific evaluation, reasonable planning and professional execution, the service life of Ultra Sleeve Anchor can be effectively extended to ensure that its important role in the building structure can be fully utilized.

Contact Us