Why is the corrosion resistance of Bolt Heavy Duty Shield Anchor so strong

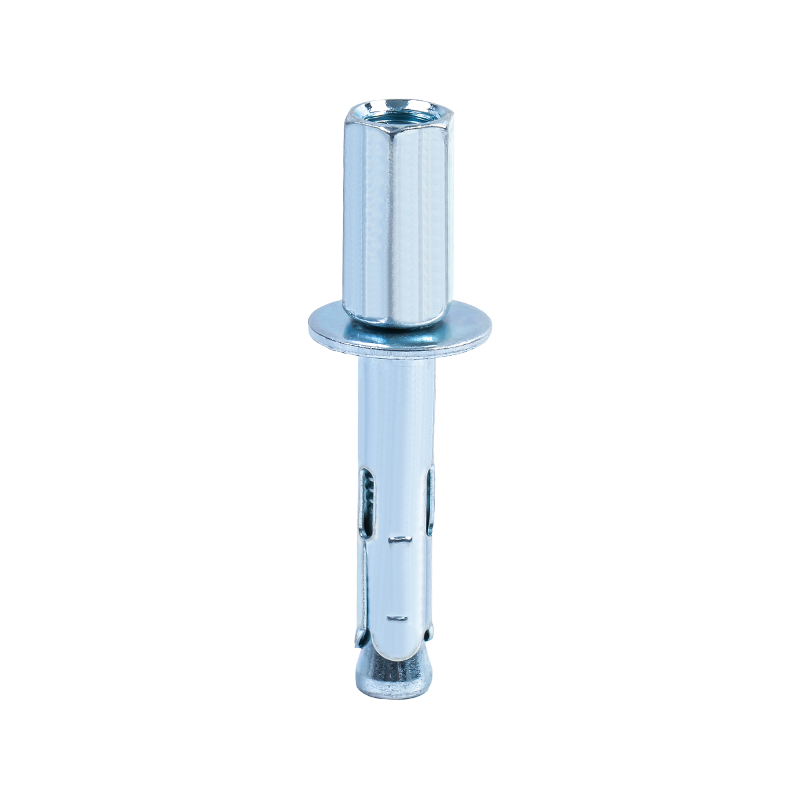

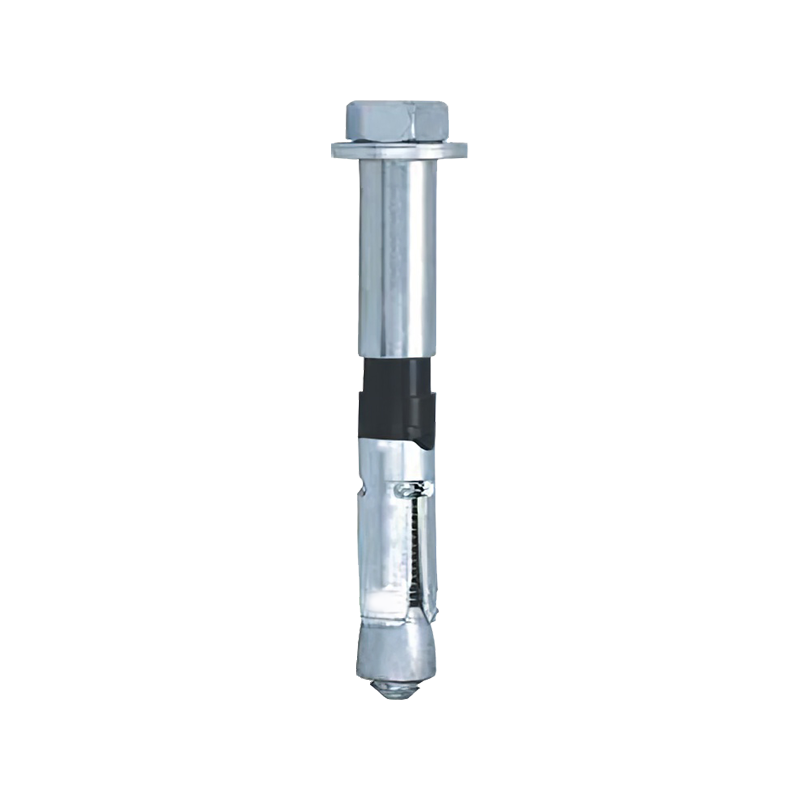

2024-10-23In the field of modern engineering, especially in projects facing harsh environmental conditions, the corrosion resistance of materials has become an important criterion for measuring their quality and application value. Bolt Heavy Duty Shield Anchor is an anchoring system designed for high loads and extreme environments, and its excellent corrosion resistance is particularly eye-catching.

The corrosion resistance of Bolt Heavy Duty Shield Anchor is due to its carefully selected materials. The bolt body is usually made of high-strength, corrosion-resistant alloy steel. This steel not only has excellent mechanical properties, but also can maintain stable chemical properties in harsh environments such as moisture and salt spray, and effectively resists corrosion erosion. At the same time, the material of the shield has also been specially treated, such as galvanizing, stainless steel coating, etc., which further enhances its corrosion resistance and provides an additional protective barrier for the bolt.

In addition to high-quality material selection, Bolt Heavy Duty Shield Anchor also uses advanced surface treatment technology to further enhance its corrosion resistance. These technologies include but are not limited to hot-dip galvanizing, electroplating chrome, spraying anti-corrosion coatings, etc. Hot-dip galvanizing technology effectively isolates the direct contact between steel and corrosive media by forming a dense zinc layer on the surface of steel, thereby significantly extending the service life. Electroplating chrome provides additional protection for bolts with its high hardness, high wear resistance and good corrosion resistance. Spraying anti-corrosion coatings can choose different types of coatings according to specific environmental requirements to achieve the best anti-corrosion effect.

The unique structural design of Bolt Heavy Duty Shield Anchor is also one of the key factors for its strong corrosion resistance. The design of the protective cover is beautiful and elegant, and more importantly, it tightly wraps the head and threaded part of the bolt, effectively preventing the intrusion of corrosive media such as rain, dust, and salt spray. This physical isolation method greatly reduces the risk of corrosion of the bolt. At the same time, the protective cover also has certain anti-wear properties, which can maintain its integrity during long-term use and continue to provide protection for the bolt.

The corrosion resistance of Bolt Heavy Duty Shield Anchor is also inseparable from strict quality control and testing. During the production process, each batch of products will undergo strict quality inspection and performance testing to ensure that it meets relevant standards and specifications. Especially in terms of corrosion resistance, special salt spray tests, wet heat tests and other tests simulating harsh environments are carried out to verify whether the corrosion resistance of the product meets the standards. This strict quality control system provides a strong guarantee for the corrosion resistance of the Bolt Heavy Duty Shield Anchor.

Contact Us