How to avoid parts damage during machine screw anchor disassembly

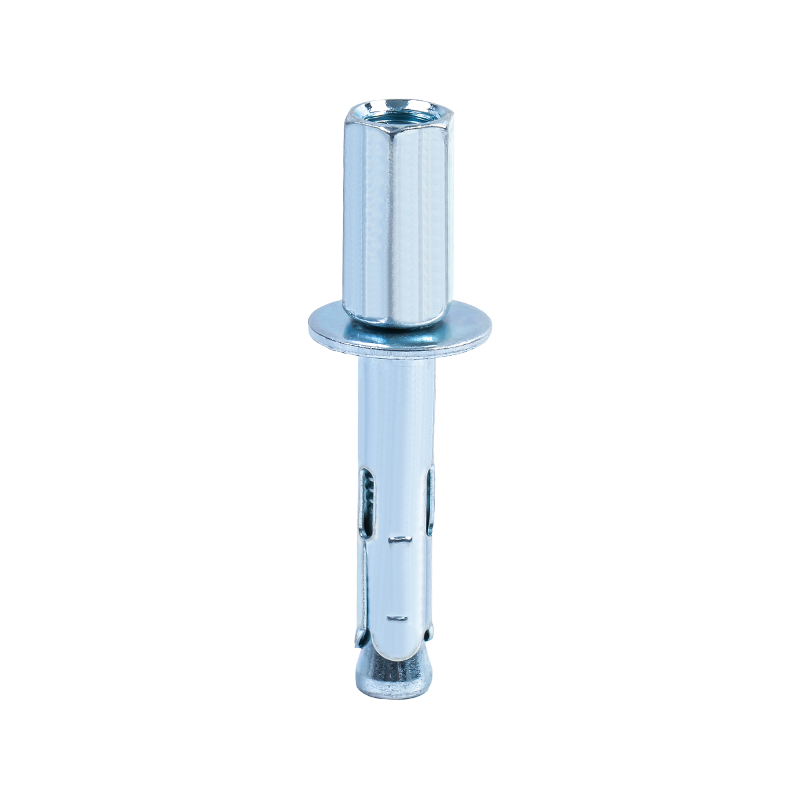

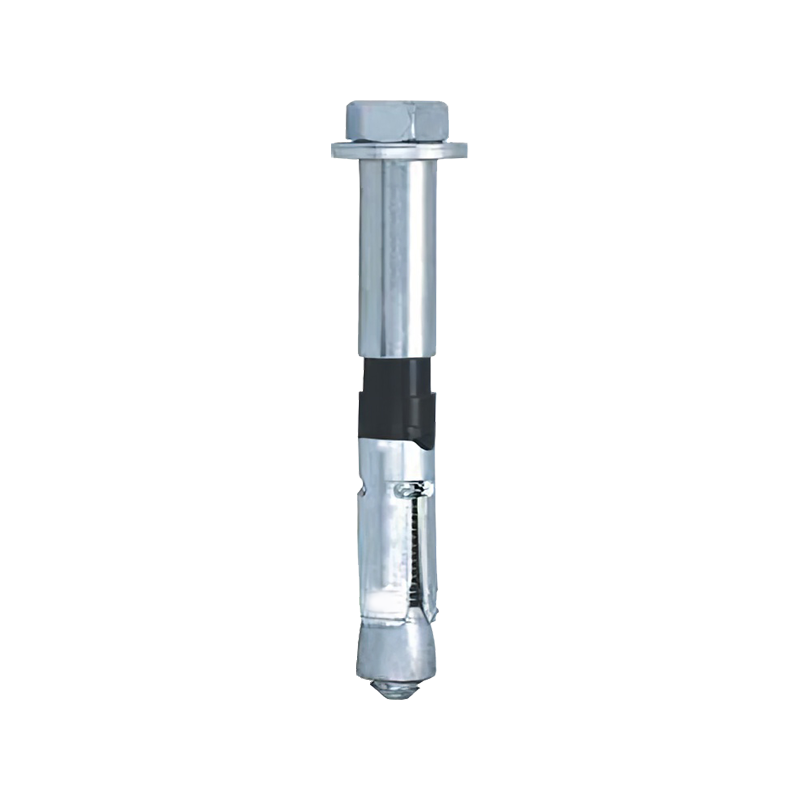

2024-12-24In modern industrial applications, Machine Screw Anchor serves as an important fastener and is widely used in various structures and equipment. In order to ensure its safety and reliability during use, the standardization of the disassembly process is particularly important.

In-depth understanding of parts characteristics and disassembly principles

Before proceeding with the disassembly of the Machine Screw Anchor, it is necessary to have a comprehensive understanding of its material properties. Machine Screw Anchor is usually made of high-strength alloy steel or stainless steel, which has excellent tensile strength and corrosion resistance. These characteristics not only affect its performance, but are also directly related to the tools and methods required during disassembly. An in-depth understanding of the material properties of parts can effectively avoid damage to parts caused by improper tools or incorrect methods during disassembly.

It is also crucial to follow sound disassembly principles. During the disassembly process, you should follow the strategy from outside to inside, from easy to difficult, and gradually release the tightening force to prevent parts from popping out or being damaged due to sudden release. In addition, developing a personalized disassembly plan based on the specific structure and application environment of the Machine Screw Anchor can significantly improve the safety and efficiency of disassembly.

Precise selection of disassembly tools and methods

Choosing the right disassembly tools is key to ensuring safe disassembly of parts. According to the specifications and materials of the Machine Screw Anchor, special screwdrivers, wrenches and other tools need to be used to avoid using unsuitable or damaged tools to prevent scratches or deformation of the parts. Regarding the disassembly method, the optimal disassembly strategy should be selected based on the fastening method of the Machine Screw Anchor and its installation environment. For example, for a threaded Machine Screw Anchor, using a special thread loosening agent can effectively reduce friction and wear, thereby promoting smooth disassembly. At the same time, controlling the force applied during the disassembly process to avoid damage to parts caused by excessive force has become an important factor for successful disassembly.

Take necessary protective measures

During the disassembly process of the Machine Screw Anchor, it is crucial to take appropriate protective measures to reduce the risk of damage to the parts. A soft material (such as a copper plate or aluminum plate) can be placed on the affected part of the part to avoid deformation or damage caused by direct impact. In addition, using professional disassembly tooling or fixtures to fix parts can effectively prevent damage caused by movement or collision during disassembly.

Pay attention to details during disassembly

When disassembling the Machine Screw Anchor, details often determine the success or failure of the job. During the disassembly process, special attention should be paid to the matching relationship between the parts and the disassembly sequence to avoid damage to the parts due to forced disassembly or reversing the disassembly sequence. At the same time, regularly check the status of disassembly tools to ensure that they are in good working order to prevent damage to parts caused by tool damage.

Contact Us