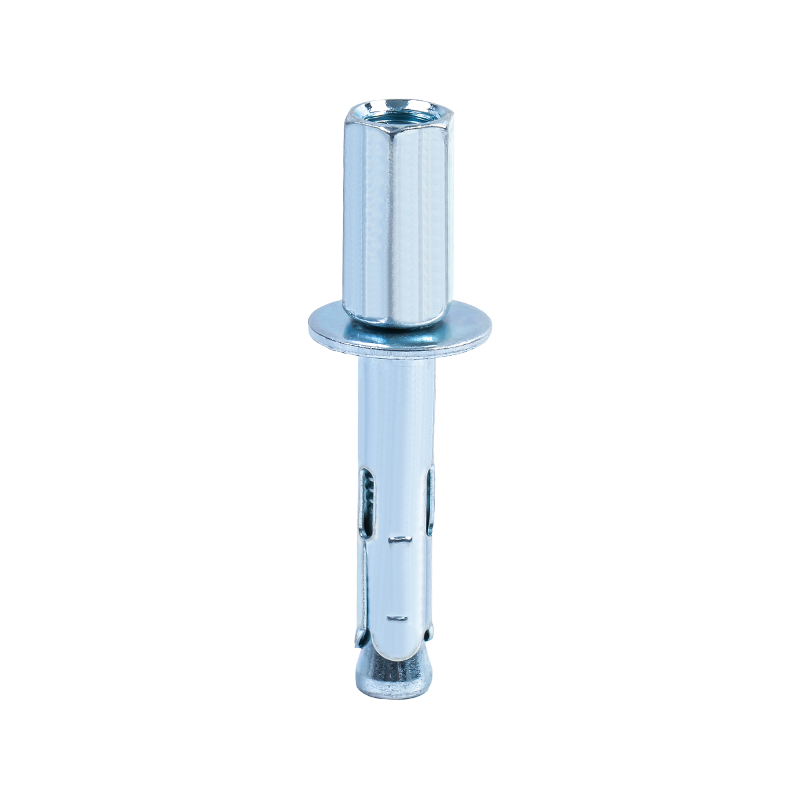

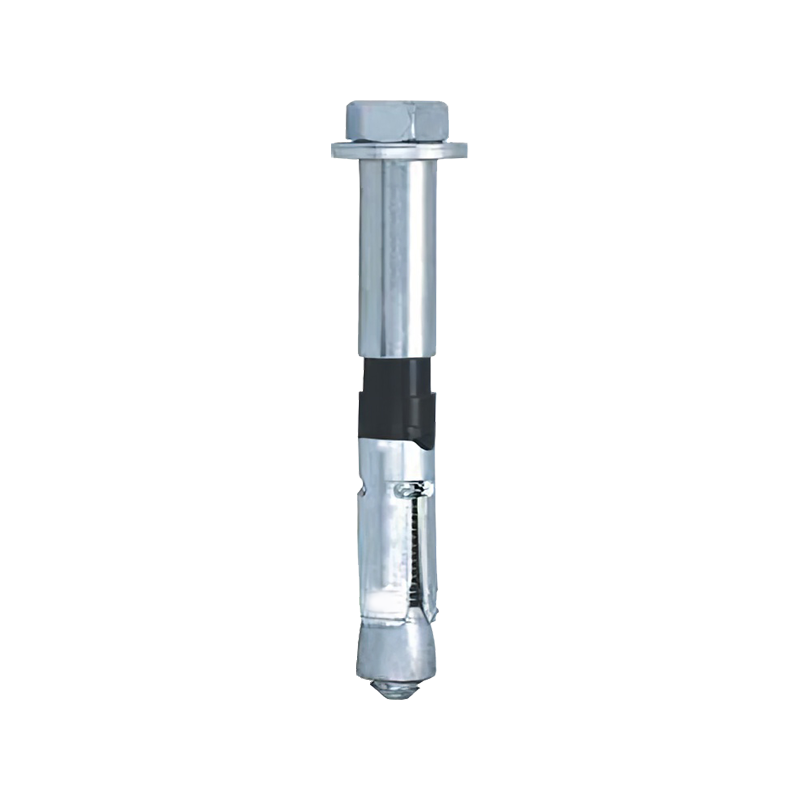

What are the precautions when disassembling the machine screw anchor

2024-12-17Before disassembling the Machine Screw Anchor, adequate preparation is the key to ensuring the efficiency and safety of the entire process. The following are professional suggestions for disassembly operations, covering environment selection, equipment cleaning, structural understanding, precautions during disassembly, and post-disassembly processing and inspection.

Preparation before disassembly

Environment selection

Choosing a suitable working environment is the basis for the success of disassembly operations. The ideal work location should be free of wind, sand, and dust, and frequent entry and exit of idle personnel should be avoided. This will help reduce the impact of external factors on disassembly tools and parts. In addition, ensure that the floor of the workplace is kept clean and avoid the presence of pollutants such as mud and oil to prevent potential damage to disassembly tools and parts.

Equipment cleaning

Before disassembly, the mechanical equipment must be thoroughly cleaned externally, especially the parts connected to the Machine Screw Anchor. The purpose of cleaning is to remove impurities and dirt that may affect the disassembly accuracy or cause damage to parts, and ensure the smooth progress of the disassembly process.

Understanding the structure

Before disassembly, it is essential to have a deep understanding of the structure, performance, and working principle of the Machine Screw Anchor and the equipment it is in. This not only helps to formulate reasonable disassembly steps, but also avoids part damage or personal injury caused by blind operation.

Precautions during disassembly

Choose reasonable tools

When disassembling the Machine Screw Anchor, be sure to use special or suitable disassembly tools, such as screwdrivers, wrenches, etc. The use of improper tools may cause deformation or damage to the parts. For specially designed Machine Screw Anchors, specific disassembly tools or methods may be required to ensure the safety and effectiveness of the disassembly process.

Protect the surface of the parts

During the disassembly process, special attention should be paid to protecting the machined surfaces of the Machine Screw Anchor and its connected parts. Brute force or improper methods should be avoided to prevent scratches or deformation on the surface of the parts, which will directly affect their subsequent performance.

Follow the disassembly sequence

The disassembly of the Machine Screw Anchor should follow a certain sequence, and it is usually recommended to go from outside to inside and from easy to difficult. During the disassembly process, the tightening force should be gradually released to avoid popping out or damage to the parts due to sudden release.

Pay attention to safety measures

During the disassembly operation, the operator should wear necessary protective equipment, such as gloves and goggles. At the same time, ensure the safety of the working area to prevent potential safety hazards such as falling from heights and being hit by objects.

Post-disassembly processing and inspection

Classify and store parts

The disassembled Machine Screw Anchor and its connected parts should be stored in categories to avoid confusion. For vulnerable parts or precision parts, it is recommended to store them separately and take corresponding protective measures to ensure their performance in subsequent use.

Check the status of parts

After disassembly, the Machine Screw Anchor and its connected parts need to be fully inspected to confirm whether they are damaged, deformed or worn. For damaged parts found, they should be replaced or repaired in time to ensure the smooth progress of subsequent operations.

Record the disassembly process

For the complex disassembly process of the Machine Screw Anchor, the disassembly steps, problems encountered and solutions should be recorded in detail. This will not only help the subsequent installation and maintenance work, but also significantly improve work efficiency and ensure the smooth progress of similar operations in the future.

Contact Us